Thanks to its experience in naval magnetism field coming from some 180 degaussing systems designed, manufactured and installed, IFEN is today capable of undertaking full responsibility for the supply of magnetic compensation systems meeting Customer's requirements and specific magnetic protection levels for combatant and auxiliary steel hulled vessels (DGM5 systems) and MCM / low signature vessels (DGM4 systems).

During more than fifty years activity, the Naval Magnetism Division has acquired a wide, complete and innovative know-how in the different fields of magnetism, such as:

- design, development of new innovative degaussing technologies and of the related degaussing control equipment, systems and utilities;

- development of project tailored Magnetic Silencing Plans and provision with full assistance for their correct application;

Vintage Gyro Degaussing Control (60's)

Vintage Gyro Degaussing Control (60's)New DGM5 PAU (Nansen Class)

Extracted from paper presented by IFEN at EMSS 2007

- research and implementation of empirical, theoretical and computational methods for magnetic modeling of equipment, system and steel hulled ships;

- design, development and construction of equipment and system for magnetic measurements.

Thanks to such a really unique experience, comforted and validated by the success that has crowned all the activities and projects to which IFEN has contributed, the Naval Magnetism Division is actually more and more able to provide a complete assistance on magnetism, both for modeling and estimate, and for the development of Magnetic Silencing Plans which provide detailed procedures for designing, provisioning, working and storing low signature equipment, system and vessels.

US Navy Official Plank Owner

DGM5 PAU

Concerning degaussing systems, IFEN supplies all the necessary efforts and hardware - by designing and manufacturing automatic control equipment, solid state power amplifiers, magnetic sensors and compass compensation units - up to complete system installation, testing and calibration.

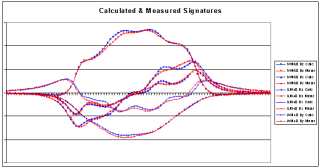

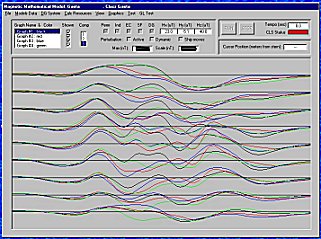

Starting from theoretical model and calculations, by means of specialized software tools - designed, developed and validated by IFEN experts - Naval Magnetism Division estimates the ship's undegaussed signature and processes the most effective degaussing system project.

Further theoretical and computational results as well as system project are validated by comparison with historical experimental data and/or by means of measurements made in the Land Based Magnetic Range on magnetic scaled down models.

Finally, after the onboard installation and testing of the degaussing system, Naval Magnetism Division performs system calibration at Degaussing Range within the Customer's values.

Mathematical Magnetic Model Estimates

Scaled Down Magnetic Model under Measurement

CLDG upgrade of DGM4 & CLDG sensor

During the last decades Naval Magnetism Division has also studied and developed Closed Loop Degaussing.

IFEN CLDG solution has been experimentally demonstrated and successfully tested by upgrading the DGM4 system installed onboard the Rimini ship of the Italian Navy Gaeta Class.

Currently, IFEN is able to offer the most innovative degaussing system technologies, based on new generation degaussing control equipment both for steel hulled ships and low signature vessels.

DGM5

DGM4-L