IFEN Ing. Amedeo Lia SpA Industria Forniture Elettriche Navali started in 1951.

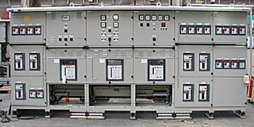

IFEN's naval experience has included the design and construction of electrical equipment such as main and frequency conversion station switchboards, automation and remote control panels, power distribution cabinets and similar equipment.

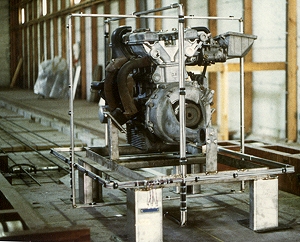

Design, construction and used components meet Italian Navy specifications and are qualified to such specifications. Particularly, vibration is in accordance with MIL-STD-167-1 and shock level is in accordance with MIL-S-901.

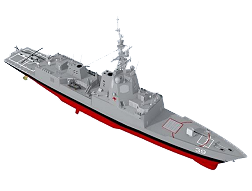

IFEN was involved just from the beginning with Naval Magnetism Topics and designed and produced magnetic protection systems (DG Systems ) for steel surface vessels and low magnetic signature MCM vessels of Italian Navy and foreign Navies.

During the past fifty years of our corporate experience base, we have designed, manufactured, tested, installed and calibrated degaussing systems for over 100 ships.

IFEN activity has grown during the years, and includes degaussing equipment design and construction, DG coil design and on board installation of the overall system, undertaking full responsibility of meeting the Customer's requirements and specific magnetic protection levels.

Thanks to such a complete experience in the naval magnetism field, IFEN is capable of undertaking full responsibility for the supply of magnetic compensation systems meeting the Customer's requirements and a specific magnetic protection level.

Particularly, for low magnetic signature vessels IFEN is currently supplying the new DGM4-L automatic degaussing control, last born of the DGM4 family, while for steel hulled ships various versions of the new DGM5 automatic degaussing control are available, to suite specific needs and Customer's requirements.

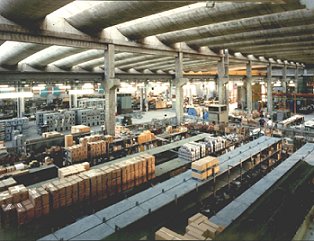

IFEN headquarters are in Ceparana (La Spezia), ITALY, where all the necessary activities, facilities and R&D resources are provided for an effective and successful design, contruction and testing of our products.

IFEN design and production were specialized on custom ruggedized electric and electronic equipment, capable of withstanding to particularly hostile environment.

Compliance to the most severe military standards for high shock, vibrations, temperature and humidity, and EM compatibility was and is an outstanding aspect of our products, as demonstrated by their successful testing.

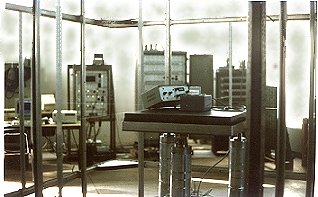

All IFEN's products are designed, manufactured and tested at IFEN's own facilities where a technical department, laboratories for enviromental testing, and a shop are available.

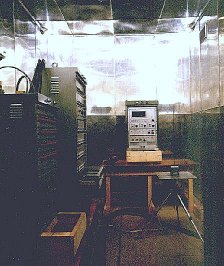

Concerning Naval Magnetism field, IFEN has established a dedicated Magnetism Laboratory for development and study of mathematical models and computational approach to electromagnetism topics and experimental validation of new degaussing techniques and equipment.

Our Naval Magnetism Division particularly comprises the Land Based Magnetic Range, normally involved in magnetic DC and AC signature measurements and deperming treatments, and also used for test and validation of mathematical modelling algorithms.

Concerning degaussing equipment and magnetic sensors, IFEN bases its design and development capabilities on the Naval Magnetism Division, which in turn avails itself for electronic design, development and prototypes construction of an Electronic Design & Development Section.